- Get link

- X

- Other Apps

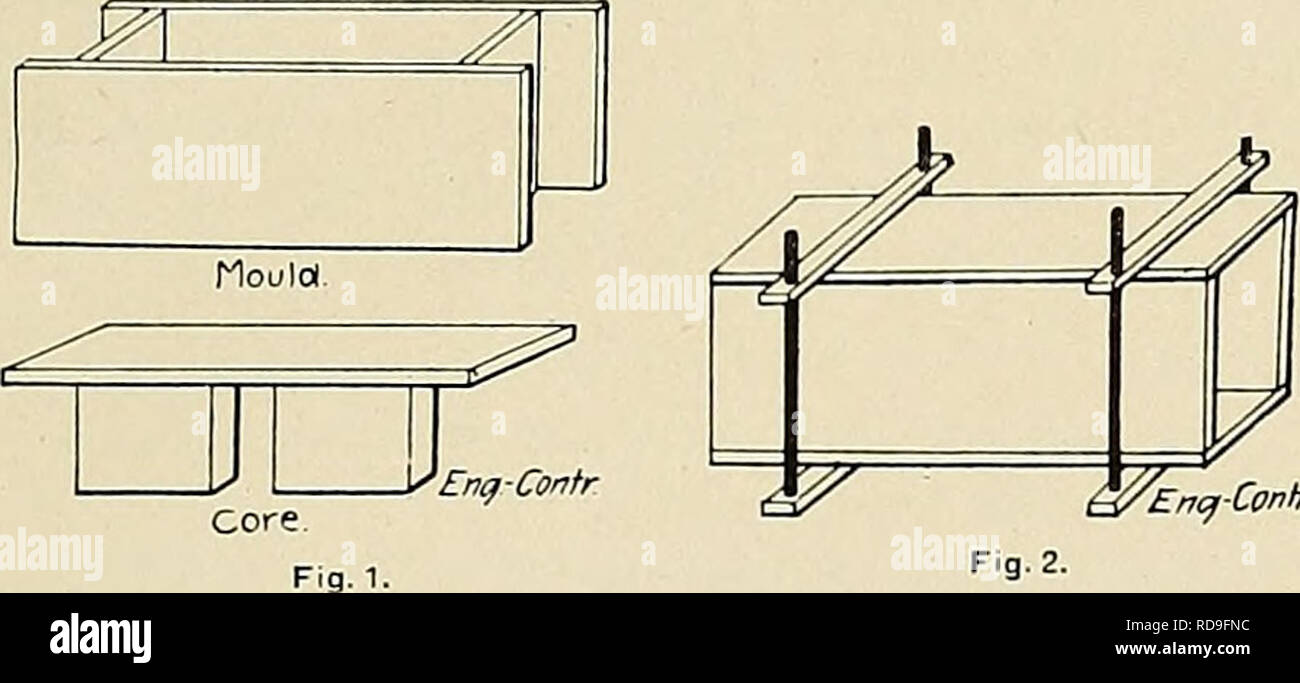

Molds made from plywood and sheet metal are quite easy to build yourself and cost much less. There are five common types of concrete available at building supply stores.

Concrete Block Types Concrete Block Block Making Machine

Concrete Block Types Concrete Block Block Making Machine

Concrete block calculator formula.

How to make concrete blocks. For best drying results cover the molds with plastic wrap. BlockArea BlockLength times Block. ---Welcome to the official.

Lightweight concrete blocks are made by adjusting the ratio of the concrete mix with a lightweight aggregate like Perlite. Cut three 1-inch wide pieces of MDO to use as side supports. Id suggest building forms for the walls base from 2 X 8 boards and then using the same lumber for the block forms after the footer is done.

Decide what size you will make the mold. They must be measured accurately and the right amount of water added. Mixing good concrete requires that the ingredients be combined in the right proportions.

If the molds are small pour the cement mix into a wheelbarrow and fill the molds with your shovel. Scoop the excess concrete mixture using a plywood plank at the open face of the mold. Several molds will make the concrete work go a lot.

Then watch as Jason Hodges learns from a pro in the art. WallArea WallLength times WallHeight. You can use pit or fine river sand coarse sand up to 5mm in size or stones that are no bigger than 10mm for hollow bricks or 13mm for solid bricks.

Usually you can make concrete bricks with just coarse sand but a combination of aggregates can also be used. Making concrete or cement blocks from hand molds is the simple way to get started in the concrete block business. Pour the concrete mixture in to the mold and stir or vibrate the mold so that the concrete gets settled in the mold and reaches the extreme corners.

Making the raw concrete block. Cut a square or rectangular piece of MDO for the base 3 12-inches longer and wider than the desired block size. To make bricks from concrete form a mold for the bricks using strips of plywood and lumber.

Pour your foam cement mixture into the molds. After that mix the concrete in a wheelbarrow and shovel it into the mold. If you are using the concrete indoors or in a place unaffected by weather then a full lightweight mix is acceptable.

Now you can buy cement block molds from dealers on the internet or for a lot less money you can make your own. The molds you can buy will generally be plastic or cast metal and are not cheap. When you make your first batch of bricks try to use coarse sand only.

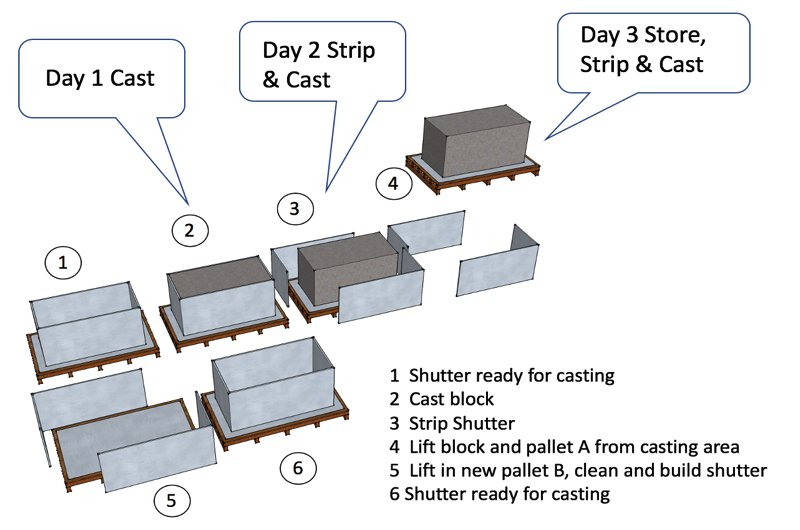

In Figure 7 the finished blocks are being moved to the curing racks. Double-headed are designed to be easier to remove than regular nails which will make dismantling the form that much easier once the concrete sets. Make the rear piece 2-inches shorter than the width of the base and the two side pieces each as long as the base sides.

This will be the block form. Want to learn how to make your own concrete sculptures for the outdoors. The calculator first works out the area of the wall based on the measurements you provide.

And the area of each concrete block otherwise known as a cinder block or cmu. Level the open surface smooth by running the plywood plank across it. Using double-headed nails attach the pieces into a box shape.

Combine the three ingredients in the crafting interface as follow with four pieces of sand and four pieces of gravel needed for each batch of eight blocks of concrete powder. With that in mind the amount of aggregate substitution depends on the type of project. You can also make concrete blocks from hand molds and even start a part time business.

For more production you can build a concrete block making machine from. Once youve built the mold spray form release oil on the inside so the concrete doesnt stick to the wood. The dye goes into the center.

In Figure 6 the operator bears down on the ejector and simultaneously presses a foot pedal to raise the mold off the formed blocks.

How To Make Lightweight Concrete Blocks Block Making Machines

How To Make Lightweight Concrete Blocks Block Making Machines

Make Your Own Concrete Blocks Do It Yourself Mother Earh News

Make Your Own Concrete Blocks Do It Yourself Mother Earh News

Concrete Blocks In Architecture How To Build With This Modular And Low Cost Material Archdaily

Concrete Blocks In Architecture How To Build With This Modular And Low Cost Material Archdaily

The Cuba Review The Cuba Review 15 Making Concrete Blocks In Cuba A Good And Profitable

The Cuba Review The Cuba Review 15 Making Concrete Blocks In Cuba A Good And Profitable

How To Make Concrete Bricks And Blocks Concrete Bricks Mix Concrete Brick

How To Make Concrete Bricks And Blocks Concrete Bricks Mix Concrete Brick

Concrete Blocks How To Make Them Yourself Diy Project Jadi Astute

Concrete Blocks How To Make Them Yourself Diy Project Jadi Astute

How To Make Concrete Blocks Fibo Intercon Batching Plant

How To Make Concrete Blocks Fibo Intercon Batching Plant

How To Make Concrete Blocks Block Making Machines Globmac

How To Make Concrete Blocks Block Making Machines Globmac

How To Make Bricks From Concrete 8 Steps With Pictures

How To Make Bricks From Concrete 8 Steps With Pictures

How To Make Your Own Concrete Blocks Waysto Digital

How To Make Your Own Concrete Blocks Waysto Digital

How To Build A Concrete Wall Diy Projects Youtube

How To Build A Concrete Wall Diy Projects Youtube

Comments

Post a Comment